IDUS 209

In this course, I learned essential skills for crafting models using digital and physical methods. We covered workshop tools, CAD software, and digital prototyping equipment. Emphasis was on seamless workflow between digital and physical realms, with a focus on meticulous file preparation and manipulation of components. Projects like cardboard vehicles and Bluetooth speakers provided practical applications, while access to the SCAD wood shop expanded our capabilities. Overall, it was a valuable experience that enhanced my proficiency in design and fabrication.

Timeline

Course

Instructor

Role

Spring 2024

IDUS 209

William Woods

Team Lead

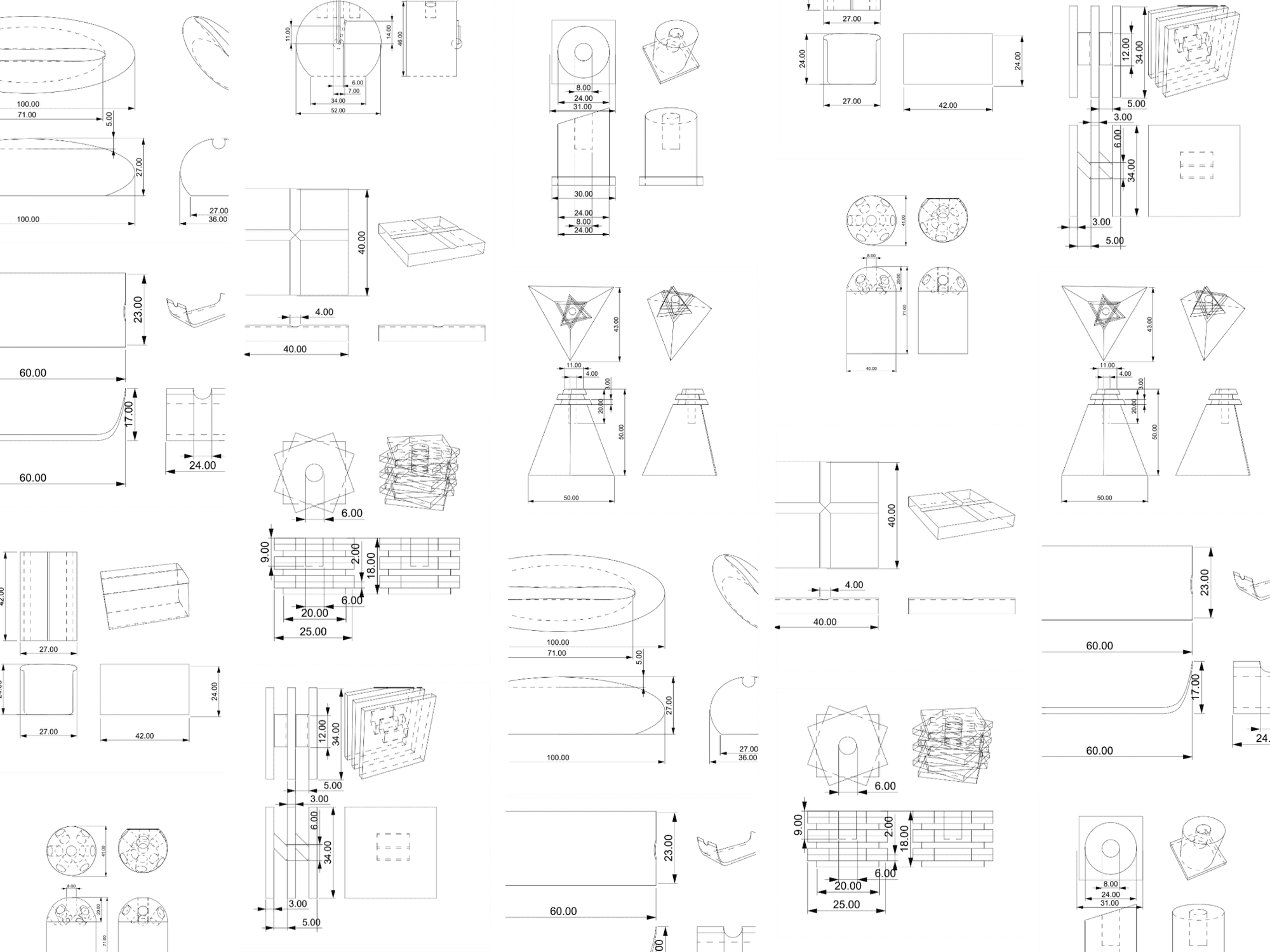

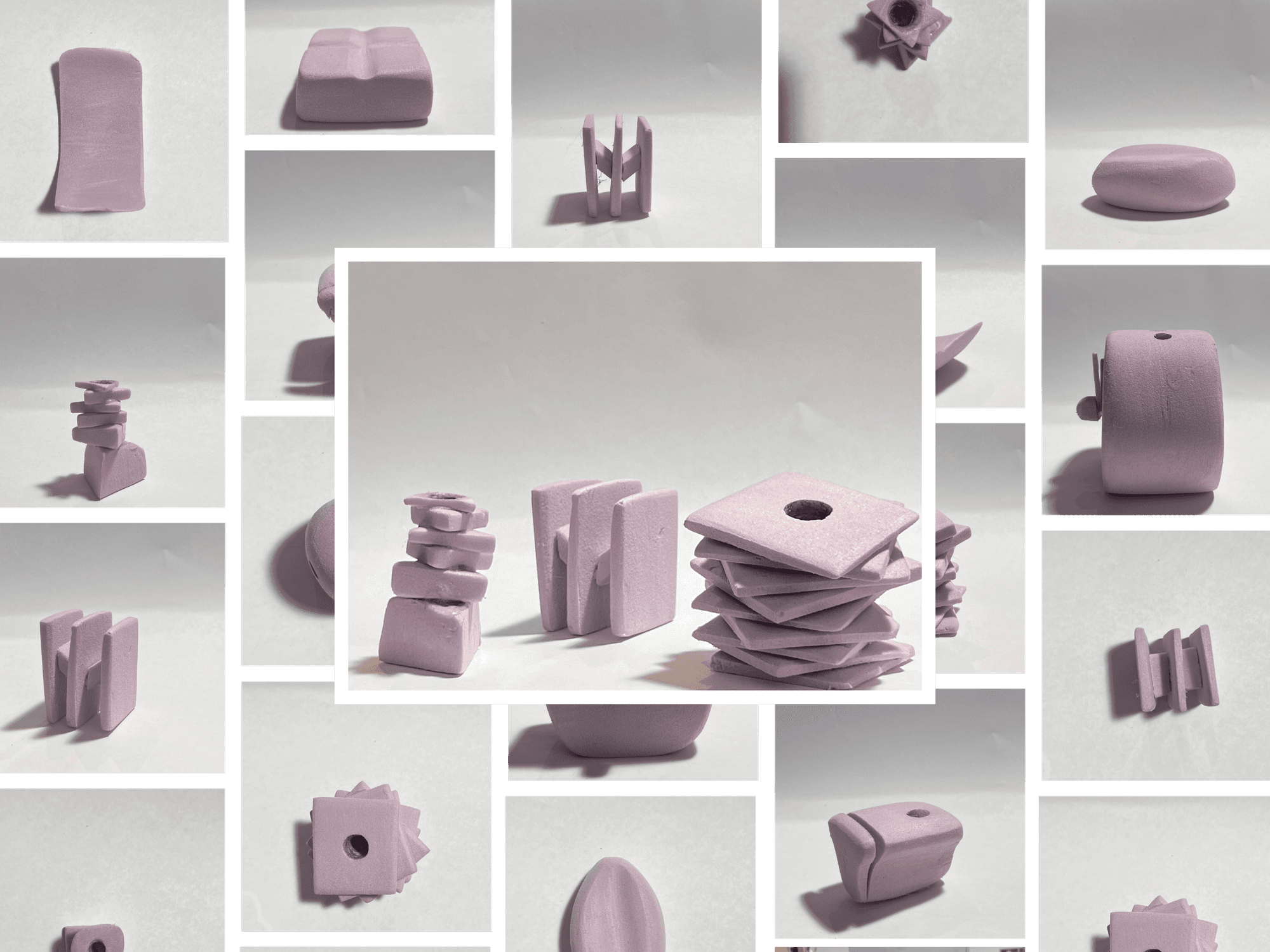

Pink Foam

From digital design to physical creation, I explored the versatile realm of pink foam by making 10 pink foam pen holders. Beginning with digital renders, I transitioned to hands-on carving, meticulously crafting intricate designs with precision tools. This process bridged the gap between virtual blueprints and tangible sculptures, emphasizing the importance of craftsmanship in design realization.

Materials

Pink foam and Metal weights

Tools

Rasp, Sandpaper, Dremel, and Hot Glue

Software

Rhinosouers

3D Models

Final Models

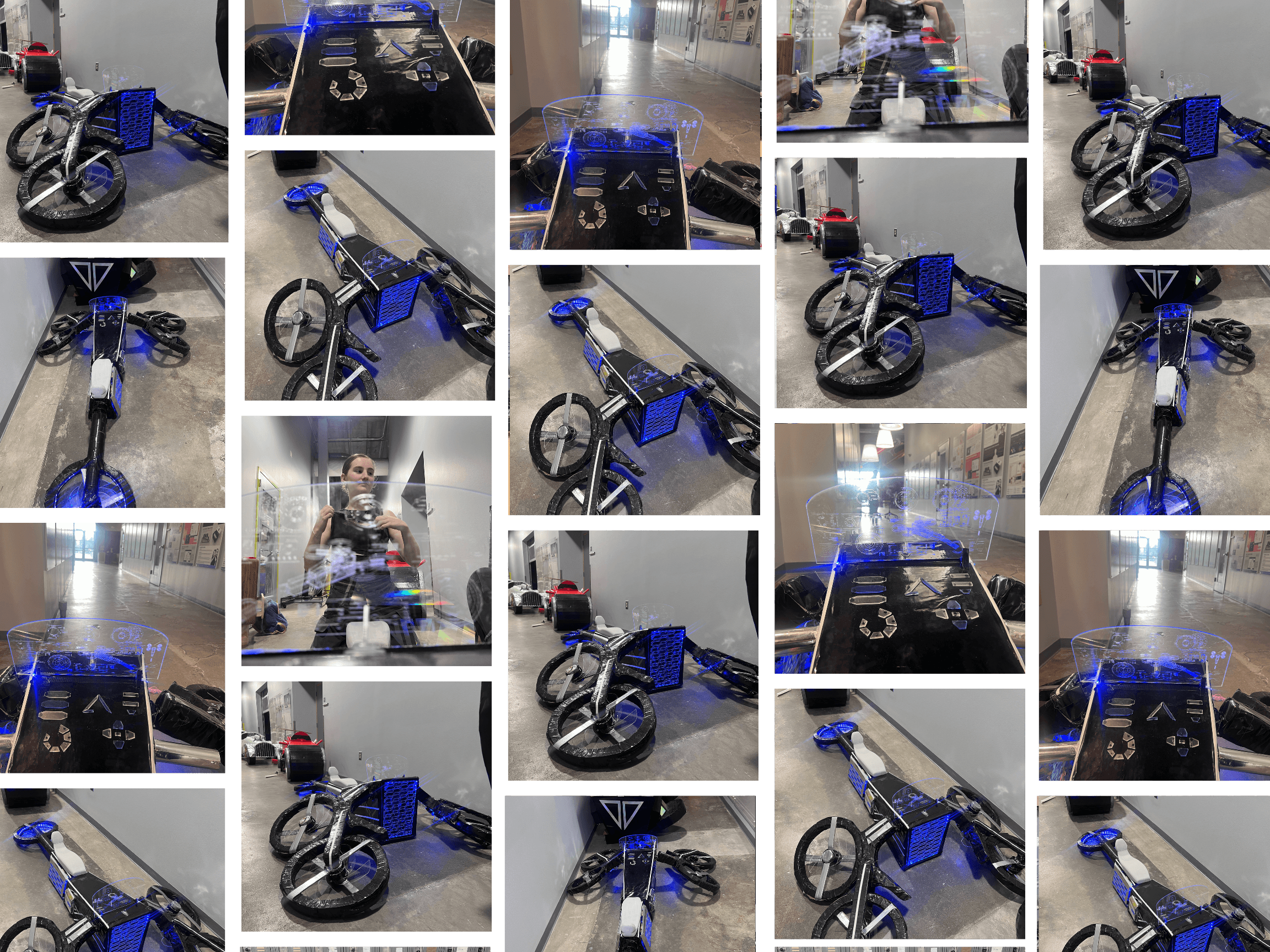

Hard Core Foam Core

Our mission was to create an innovative vehicle for group journeys crafted from cardboard and foam board. The process began with detailed hand sketches, which evolved into digital renders, visualizing a futuristic mode of transportation. We then transitioned to hands-on construction, cutting and assembling each component with hand tools, ensuring both structural integrity and aesthetic appeal. Each step involved meticulous refinement to strike the right balance between form and function. The final product, reminiscent of something out of a sci-fi novel, is the motorbike of the future.

Team

Xander Grant, Bentley Joseph, Shaoxiong Guan, Finley Peplinski, and Arnav Khair

Materials

Cardboard, Carpet tubing, Epoxy, Wrapping paper, Duct tape, and LEDs

Tools

Dremel

Software

Rhinosouers

Work in Progress

Final Models

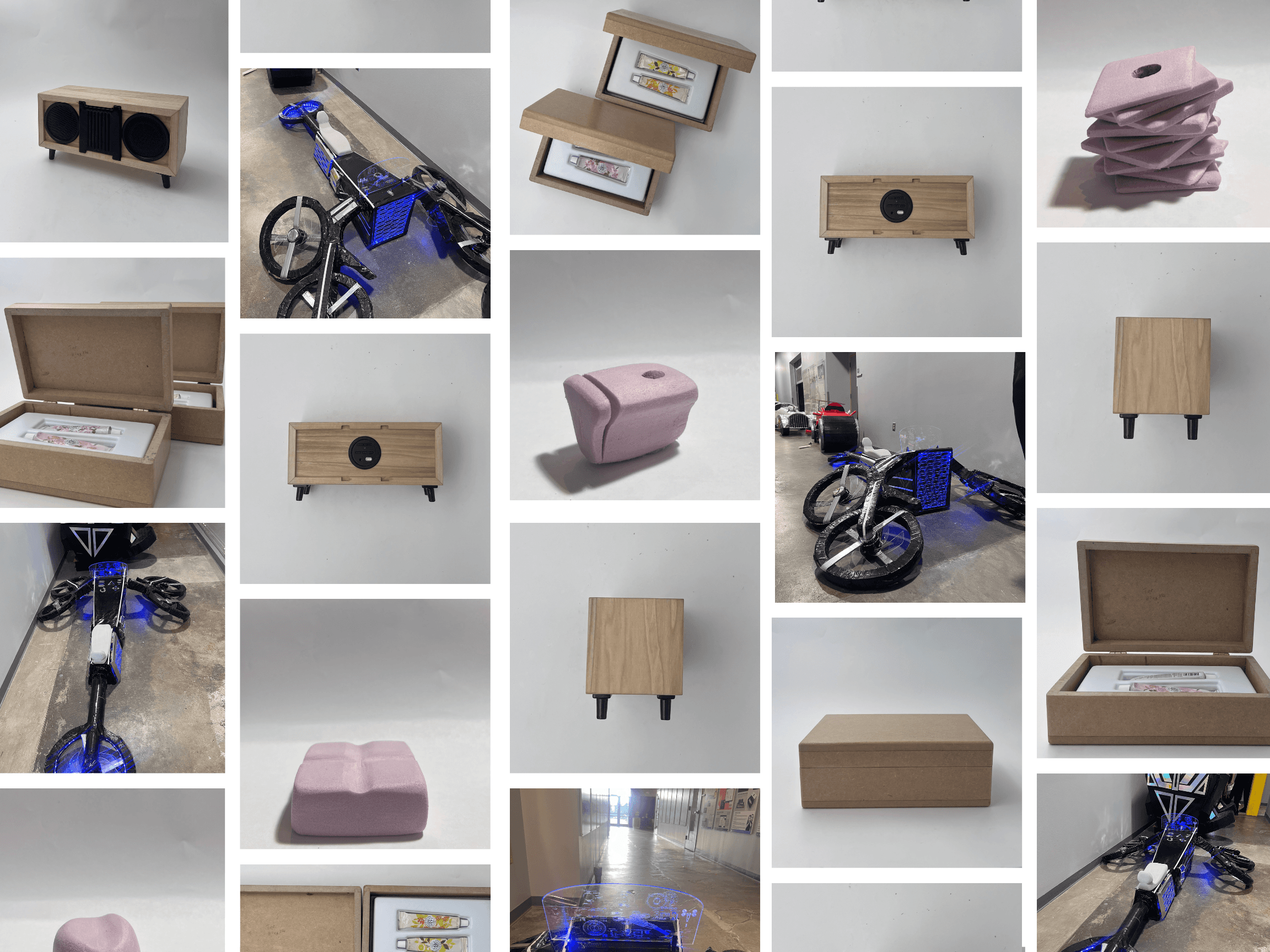

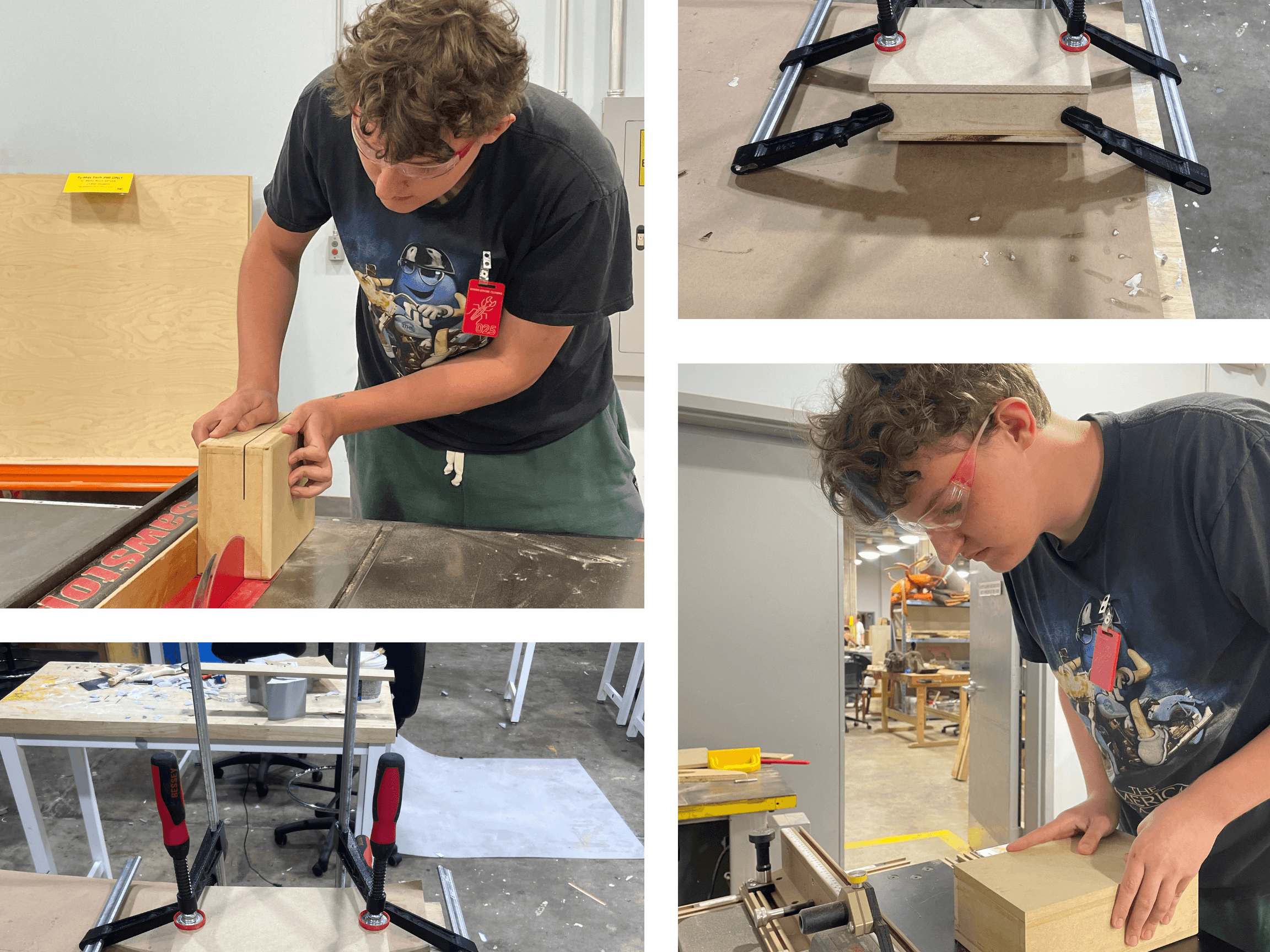

Wooden Box

My experience with The Wooden Box was an intricate journey from start to finish. Given a model to replicate, I began by engraving a wooden insert with a laser, then meticulously sanding and gluing it into place. Following this, I vacuum-formed Styrene sheets onto the mold, carefully drawing and cutting the wood to incorporate intricate dado cuts for an interlocking design. After assembling and gluing the pieces together, I dedicated days to sanding until achieving perfection. Finally, layers of sealant and shellac were applied.

Materials

MDF, Plywood, Styrene sheet, Glue, Shellac, Sanding sealer, and Sandpaper

Software

Rhinosouers

Tools

Laser engraver, Table saw, Vacuum former, Bandsaw, Router, and Disc sander

Work in Progress

Final Boxes

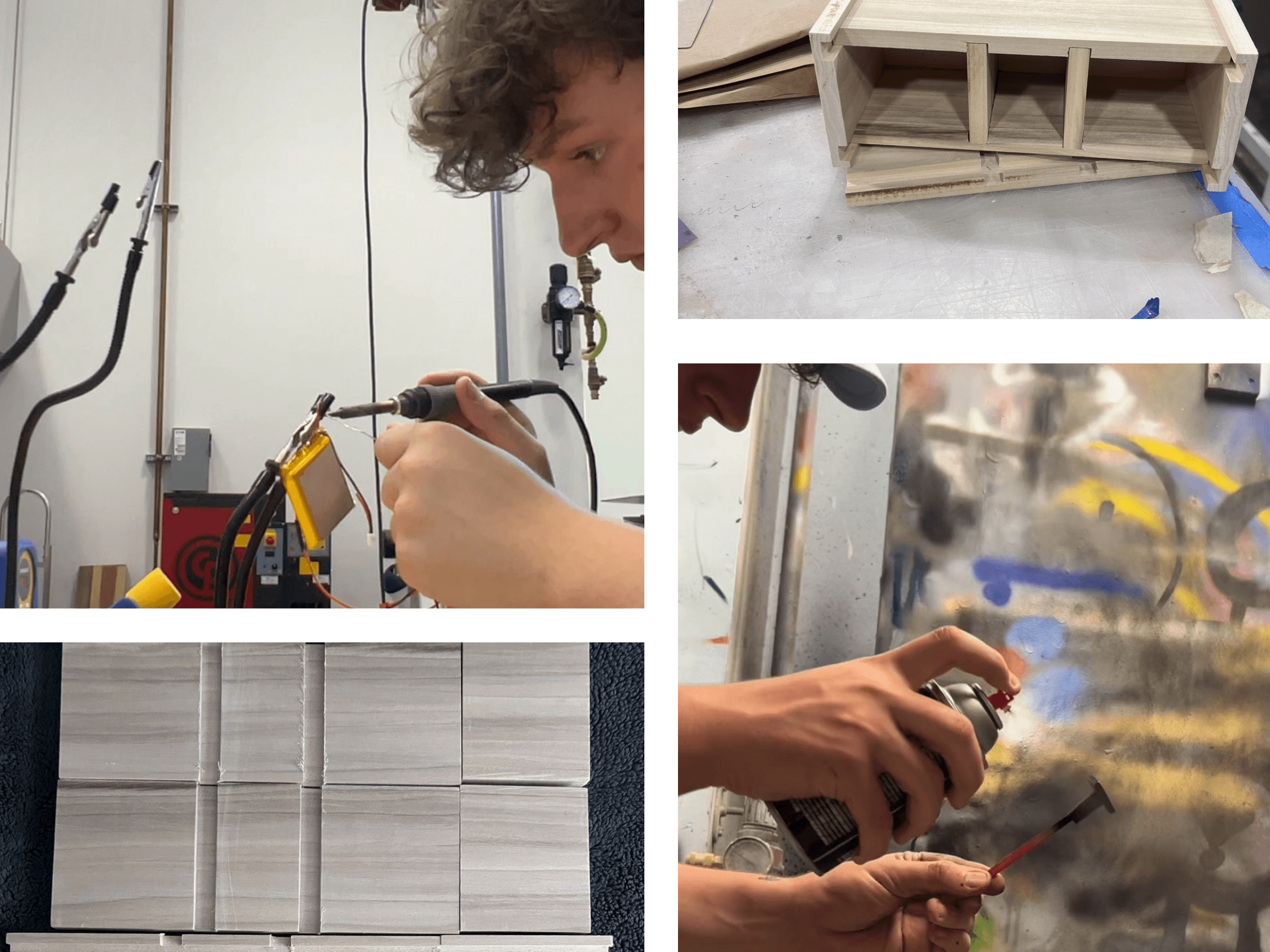

Bluetooth Speaker

From digital design to physical creation, I explored the versatile realm of pink foam by making 10 pink foam pen holders. Beginning with digital renders, I transitioned to hands-on carving, meticulously crafting intricate designs with precision tools. This process bridged the gap between virtual blueprints and tangible sculptures, emphasizing the importance of craftsmanship in design realization.

Materials

Polar Wood, Wood Glue, FDM, Body Bondo, Wood Bondo, Cutting Board Oil, Sandpaper, Primer, Spray Paint, Spray Paint 2K, Speaker Pods, Control Pod, Drill Bits, Lithium Battery Pack

Software

Rhinosouers

Tools

Table Saw, Router, Compound Miter Saw, 3D Printer, Drill Press, Hand Drill, Band Saw, Disc Sander

Work in Progress

Final Speaker

That's all for now!

You can find me elsewhere.